Air Handling Unit with Rotary Type Heat Exchanger Air Handling Unit

Product Features:

VENTAS

Air Handling Units are produced with an air flow range of 1000m3/h to 100000m3/h.

Panels and Outer Cage System

EUROVENT Certified VKS Series of Air Handling Units have 63mm sandwich panels with an outer skin of 0,8mm painted Galvanized Sheet metal and 1mm Galvanized sheet metal inside.

For panel production material, VENTAS provides galvanized, rustproof, aluminium and PVC coated sheet options. Moreover, the color of sheet metals at the outer part of units is RAL 9002.

Special aluminium profiles are used at the outer cage of air handling units. Profiles have a custom and closed design in order to reduce the internal pressure losses as much as possible and prevent from pollution that can be produced within the devices.

Corner and omega parts connecting outer cage system are designed appropriate with the structure of profiles and strengtheners and manufactured out of heat-resistant glass-strengthened composite material.

Within VENTAS Air Handling Units, air adjustment dampers with aerodynamic type blades are used which works with hidden geared impulsion system. Damper wings and frame are manufactured from aluminium profile; moreover, gear system and bearing systems are produced with a hard material resistant to heat, dust, and strong against external hits. There are special air tight seals between damper blades in order to guarantee air imperviousness.

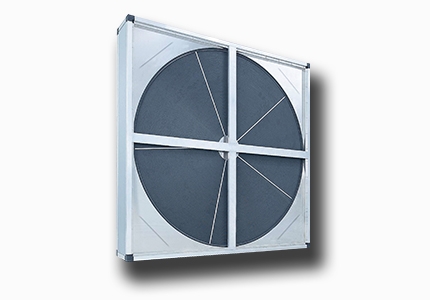

Heat Recovery System : Rotary

High Efficiency Rotors

are used for Rotary Type of heat recovery.

With thanks to type of Rotors Condensation, Enthalpy and Sorption types

are available up to 98% heat recovery

Ventilator and Aspirator Units

VENTAS air handling unit's ventilator or aspirator

units are produced in standard chamber structure. While ventilator and

aspirators can be chosen as forward or backward curved blades, radial

single/double suction fans balanced

statically and/or dynamically, they can also be designed with plug-fan.

Electrical motor of fans are montaged on to the same chassis. In order to

prevent the vibration that can be occured especially within this chamber, to

the other part of the air handling unit, rubber or spring type vibration

isolator is used at an amount and size dependent on the capacity, size, fan and

motor cycles of the unit.

Belt and Pulleys

Pulleys used in fans and motors are V-belt pulleys appropriate to DIN

2211 and TS 148 norms. Pulleys are formed in two parts. Since, after the first

part is mounted in fabric to the fan and motor spindle, the second part can be

mounted without a need for a hardware, pulley size can be made very easily upon

need.

In order to transfer power between motor and fan pulleys, narrow V-belts

(appropriate to TS 198/40 DIN 7753/1) or classical V-belts (appropriate to TS

198/1 DIN 2215) are used. Moreover, there is a belt stretching mechanism for

adjusting the belt tightness between the fan and motor to the desired and

efficient level.

Filters

Montage frames are designed for different filter classes used together

with air handling units for several different purposes. Thanks to this design,

filters can be placed very easily into their sockets with spring systems.

Moreover, with this design, any possible by-pass that can be occured at filters

are reduced to minimal levels. G3-G4 class filters used as front-side filters,

have galvanized frames, and with galvanized string connections, they are installed with increased

resistance to air flow.

Bag filters with different classes are used as second-level filters in

air handling units. Besides, they are used as first-level filters for hygienic

air handling units. Bag filters can be chosen out of F5 to F9 classes. In air

handling units, rigid filters can be used as the last filter at between classes

F5 to F9 upon need. In order to filter undesired odor, active carbon filters

both with carbon imbued panel or with cartridge, can be used.

Coils

All coils are subject to

hydrostatic tests before installation. In order for easy maintenance and

montaging, special sliding mechanism is designed. In air handling units with

cooling coils, rustproof condensation pan and polypropylene drop holder

(appropriate to DIN 7728 standards and resistant up to 130oC) is used in

standard.

Humidifier

Silencer

Please have a look on product catalogs for technical details ...